Why Augmented Reality in Manufacturing Is Transformative

Augmented Reality in Manufacturing is revolutionizing industries in 2025 by enhancing efficiency and precision. AR overlays digital data onto real-world environments, guiding workers through complex tasks. Unlike Virtual Reality, which immerses users in digital worlds, Augmented Reality enhances factory floors with real-time insights. Augmented Reality in Engineering streamlines design reviews, reducing errors by 15%, per industry studies. Virtual Reality in Manufacturing supports immersive training, while AR aids live operations. Mixed Reality in Manufacturing blends both for hybrid solutions. This section explores why Augmented Reality is a game-changer, boosting productivity and safety across manufacturing.

How Augmented Reality in Engineering Enhances Design

Augmented Reality in Engineering transforms design processes in 2025. AR tools like Microsoft HoloLens display 3D models in real-world contexts, enabling engineers to visualize prototypes on factory floors. This cuts design time by 20%, according to Siemens. Augmented Reality in Manufacturing integrates with CAD software, allowing real-time adjustments. Virtual Reality in Manufacturing creates virtual prototypes, but AR overlays them in physical spaces for practical testing. Mixed Reality in Manufacturing supports collaborative reviews across teams. AR reduces costly errors by aligning designs with production realities. This section details how Augmented Reality enhances engineering precision and innovation.

Virtual Reality in Manufacturing for Training

Virtual Reality in Manufacturing excels in immersive training in 2025. VR simulates factory environments, allowing workers to practice tasks like machine operation without risks. Augmented Reality System for Virtual Training of Parts Assembly guides trainees with step-by-step overlays, improving retention by 25%, per Boeing studies. Unlike Augmented Reality in Manufacturing, which aids live tasks, VR creates controlled training scenarios. Mixed Reality in Manufacturing combines both for versatile learning. Tools like Oculus Rift deliver realistic simulations, reducing onboarding time. This section explores how Virtual Reality transforms training, ensuring skilled, confident workers in manufacturing settings.

Mixed Reality in Manufacturing Applications

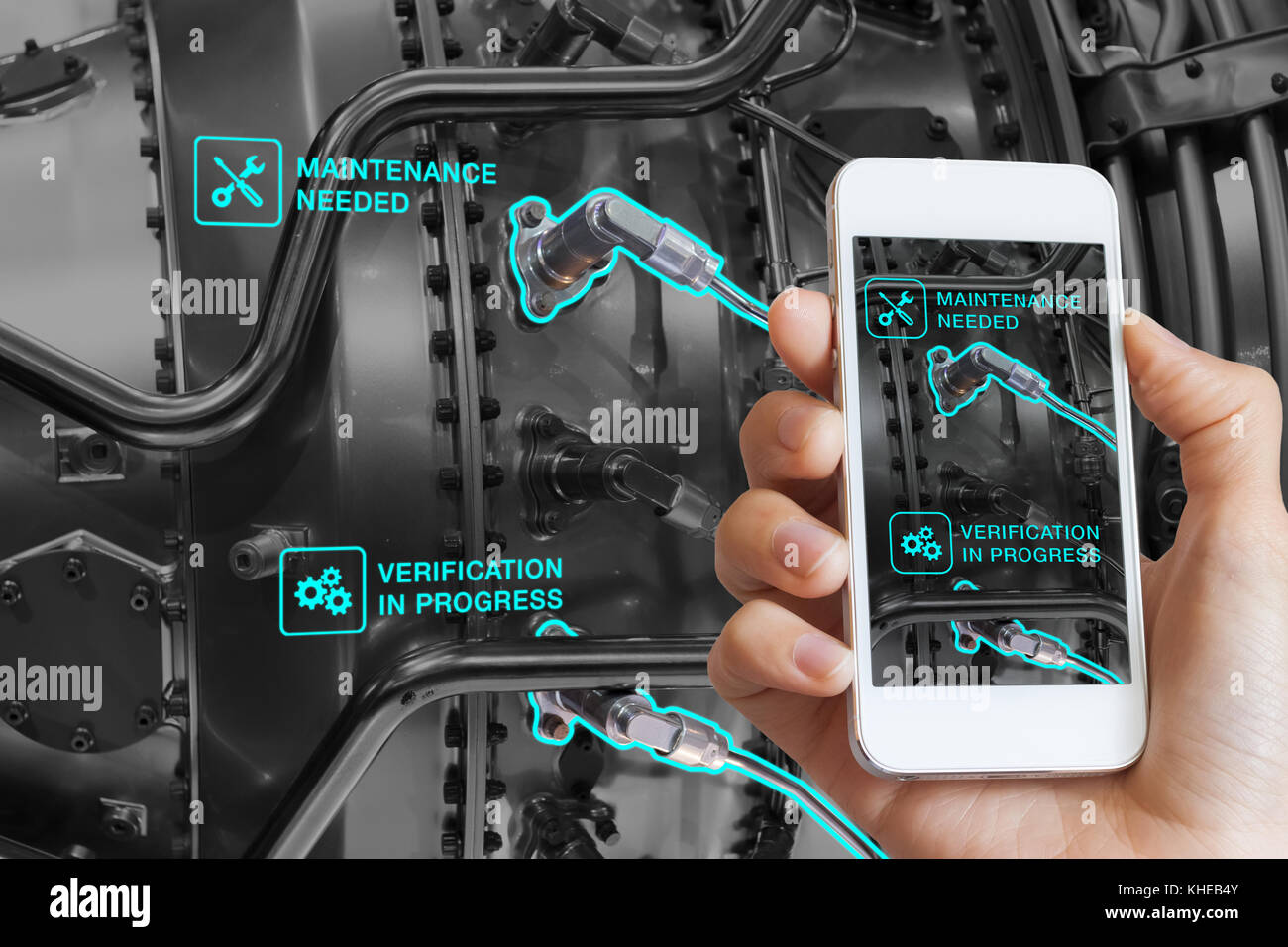

Mixed Reality in Manufacturing blends Augmented Reality and Virtual Reality for advanced applications in 2025. MR tools, like Magic Leap, enable workers to interact with holographic parts while seeing real machinery. This supports complex tasks like equipment maintenance, cutting downtime by 30%, per GE reports. Augmented Reality in Manufacturing provides real-time data overlays, while MR adds interactive 3D models. Augmented Reality in Engineering uses MR for collaborative design reviews across global teams. Virtual Reality in Manufacturing focuses on simulations, but MR bridges physical and digital worlds. This section highlights Mixed Reality’s role in boosting efficiency and innovation.

Augmented Reality System for Virtual Training of Parts Assembly

Augmented Reality System for Virtual Training of Parts Assembly streamlines manufacturing training in 2025. AR tools like PTC Vuforia overlay step-by-step instructions on physical parts, guiding workers through assembly. This reduces errors by 40%, per Airbus data. Unlike Virtual Reality in Manufacturing, which simulates entire environments, AR enhances real-world tasks. Augmented Reality in Manufacturing ensures precision in live production, while Mixed Reality in Manufacturing adds interactive elements. Free platforms like ARCore offer basic training apps. This section explores how Augmented Reality systems revolutionize parts assembly training, enhancing speed and accuracy.

AR and VR Benefits in Manufacturing

Augmented Reality in Manufacturing and Virtual Reality in Manufacturing offer significant benefits in 2025. AR improves worker efficiency with real-time guidance, reducing assembly time by 20%. VR cuts training costs by simulating hazardous tasks safely. Augmented Reality in Engineering minimizes design flaws, saving millions in rework. Mixed Reality in Manufacturing enhances collaboration, connecting remote teams via holograms. Augmented Reality System for Virtual Training of Parts Assembly boosts skill retention. Together, AR and VR increase productivity and safety, with 60% of manufacturers adopting them, per IDC. This section details how these technologies drive cost savings and innovation in manufacturing.

Where to Find AR and VR Manufacturing Solutions

Exploring Augmented Reality in Manufacturing solutions is accessible in 2025. PTC’s Vuforia and Microsoft’s HoloLens offer AR tools for factories, available via their websites. Virtual Reality in Manufacturing platforms like Unity with Oculus are found on developer hubs. Free AR tools, like Google ARCore, support small-scale projects. Check Augmented Reality in Engineering solutions on Siemens’ or Autodesk’s sites. Coupon sites like CouponUpto offer discounts on AR and VR software licenses. Industry events like CES showcase Mixed Reality in Manufacturing demos. This section guides you to sources for cutting-edge manufacturing tech.

Tips for Implementing AR in Manufacturing

Implementing Augmented Reality in Manufacturing requires strategic planning. Start with pilot projects using free tools like ARKit for small-scale Augmented Reality in Engineering tasks. Train staff with Augmented Reality System for Virtual Training of Parts Assembly to ensure adoption. Integrate AR with existing systems like ERP for seamless workflows. Test Virtual Reality in Manufacturing for training before scaling. Optimize Mixed Reality in Manufacturing for collaborative tasks with clear objectives. Monitor ROI using analytics to track efficiency gains. Join forums like Reddit’s AR/VR communities for insights. This section shares tips to successfully deploy Augmented Reality AR in 2025 manufacturing.

Conclusion

This guide to the top 7 Augmented Reality in Manufacturing trends for 2025 highlights its transformative impact. From Virtual Reality in Manufacturing for training to Augmented Reality in Engineering for design, AR and VR boost efficiency and innovation. Mixed Reality in Manufacturing and Augmented Reality System for Virtual Training of Parts Assembly streamline operations. Adopt AR and VR with tools from PTC or Unity, and explore deals on CouponUpto. Whether you’re in production or engineering, these technologies redefine manufacturing. Dive into the AR and VR revolution for a smarter 2025 factory.

.jpg)

.jpg)